Specialized tools are crucial for efficient commercial vehicle repair, catering to unique needs from tire services to advanced diagnostics and bodywork. Regular maintenance, following manufacturer guidelines, and prompt damage addressing extend lifespan, optimize performance, reduce downtime, and enhance brand image. Structured troubleshooting begins with comprehensive inspections, followed by detailed guides for complex issues, ensuring effective repairs, enhanced safety, and minimal environmental impact.

“Maximize the lifespan and performance of your fleet with advanced tips on commercial vehicle repair. This comprehensive guide delves into the essentials, including understanding specialized tools tailored for complex repairs, implementing efficient maintenance schedules to prevent downtime, and troubleshooting common issues step-by-step. By mastering these techniques, you’ll ensure optimal efficiency, reduce costs, and keep your commercial vehicles on the road longer.”

- Understanding Specialized Tools for Commercial Repairs

- Efficient Maintenance Schedules for Longevity

- Troubleshooting Common Issues: A Step-by-Step Guide

Understanding Specialized Tools for Commercial Repairs

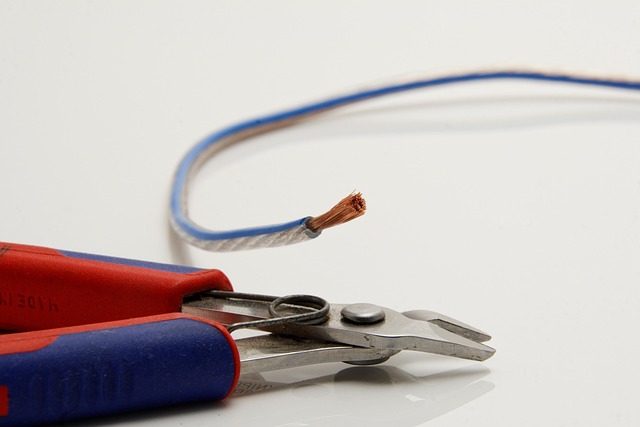

When it comes to commercial vehicle repair, understanding specialized tools is key. These vehicles, whether trucks, buses, or vans, often require unique equipment designed to handle their specific components and systems. For instance, tire services are a crucial aspect of commercial repairs due to the size and weight of the vehicles, necessitating specialized machinery for mounting, balancing, and repairing tires. Similarly, automotive repair services must include advanced diagnostics tools capable of reading complex computer systems.

Beyond mechanical repairs, commercial vehicle owners should invest in comprehensive car bodywork services. These services are essential for fixing dents, scratches, and other cosmetic issues that can affect the overall appearance and value of the vehicle. With specialized tools like hydraulic presses and precision welding equipment, skilled technicians can restore damaged body panels to their original condition, ensuring safety and enhancing the vehicle’s resale potential.

Efficient Maintenance Schedules for Longevity

Maintaining commercial vehicles on a regular schedule is key to ensuring longevity and optimal performance. Efficient maintenance schedules for these workhorses involve adhering to manufacturer guidelines while accounting for specific operational demands. Regular inspections, fluid checks, and timely part replacements are non-negotiable. By implementing structured maintenance routines, fleet managers can minimize unexpected breakdowns, reduce downtime, and extend the lifespan of their vehicles.

One crucial aspect is scheduling auto body repair and collision repair services as soon as damage occurs. Prompt attention to fender benders or more severe accidents prevents minor issues from escalating into major repairs later on. Moreover, regular car body restoration ensures that commercial vehicles maintain a professional appearance, boosting brand image and safety standards. Efficient maintenance practices not only save costs in the long run but also contribute to environmental sustainability by reducing waste and minimizing the need for frequent replacements.

Troubleshooting Common Issues: A Step-by-Step Guide

When it comes to commercial vehicle repair, troubleshooting common issues can often seem daunting. However, with a structured approach, many problems can be identified and resolved efficiently. Start by performing a thorough inspection, focusing on key areas such as brakes, tires, lights, and fluid levels. This initial check can often reveal simple yet effective solutions.

For more complex matters, follow a step-by-step guide tailored to your vehicle’s make and model. Many auto collision centers offer detailed repair manuals that walk you through processes like diagnosing engine problems, addressing electrical issues, or even carrying out collision damage repair on car bodywork. Remember, proper troubleshooting involves systematically eliminating possibilities until the root cause is uncovered. This methodical approach ensures effective commercial vehicle repair, minimizing downtime and maximizing safety on the road.

Commercial vehicle repair is a complex yet essential aspect of maintaining efficient and safe transportation. By understanding specialized tools, implementing robust maintenance schedules, and mastering troubleshooting techniques, fleet managers can significantly reduce downtime and extend the lifespan of their vehicles. These advanced tips empower professionals to navigate the challenges of commercial repairs, ensuring a reliable and cost-effective fleet operation.